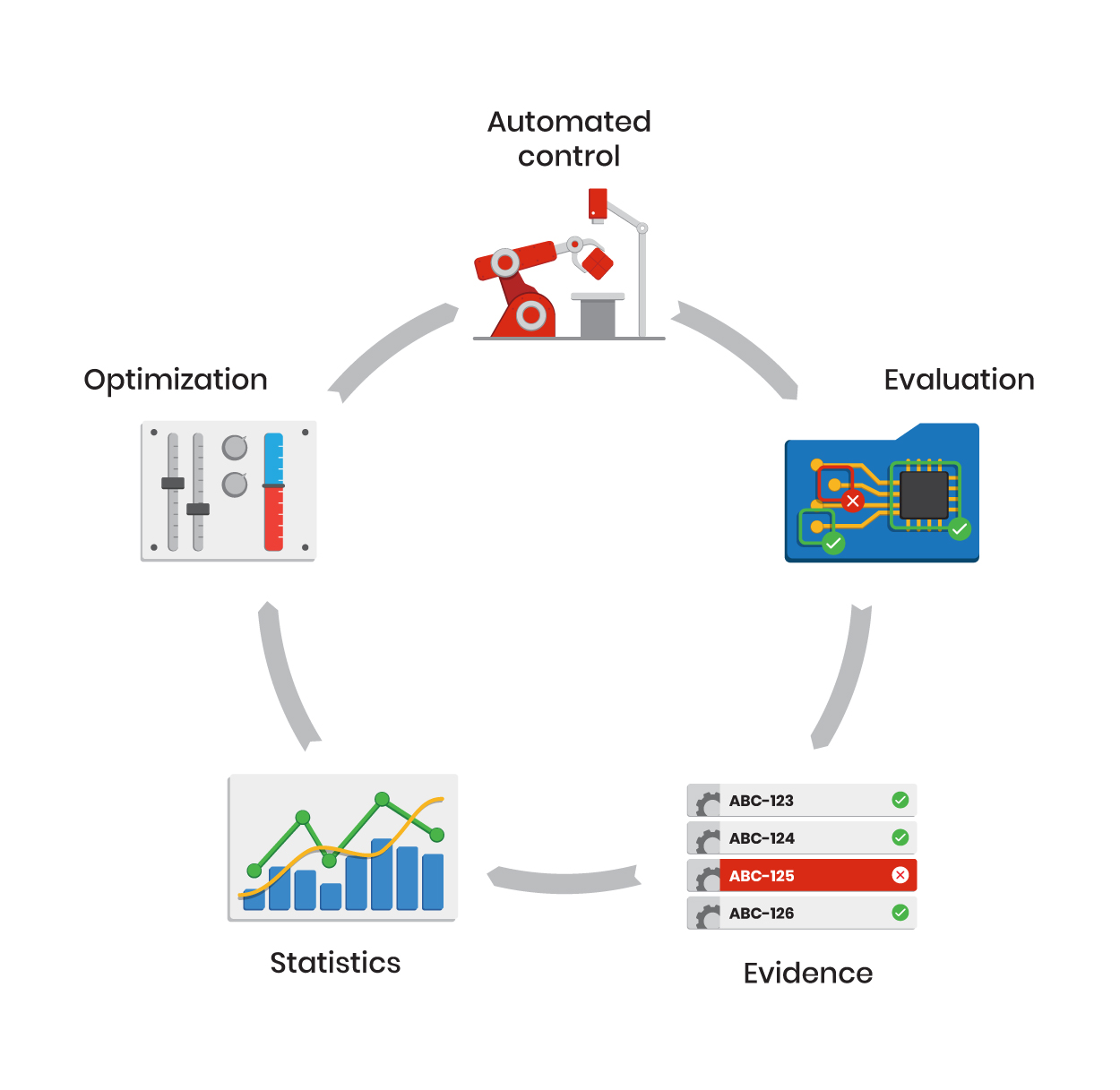

How does it work?

We design individual workstation or full robotic production lines to meet customer needs.

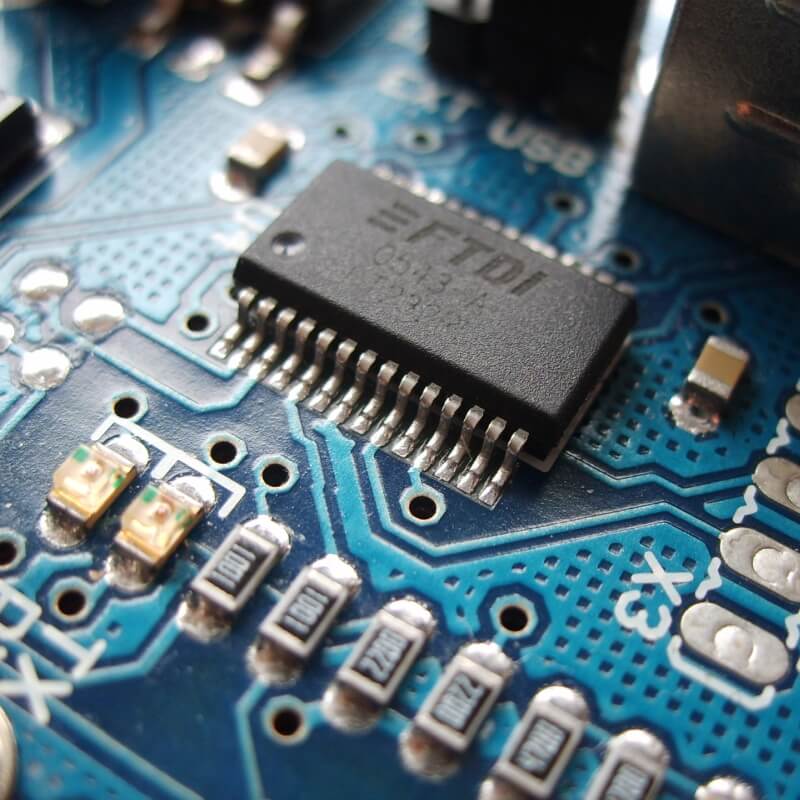

High resolution cameras, laser sensor and other measuring devices collect necessary data. Using machine vision and artificial intelligence, we can determine whether the product is satisfactory.

Processed data is stored on secure servers in the cloud or on site. You get complete evidence of production.

The results of monitoring are processed into clear statistics, which we prepare individually for every customer.

Continuously acquired statistics provide a basis for analysis and subsequent manufacturing process optimization.