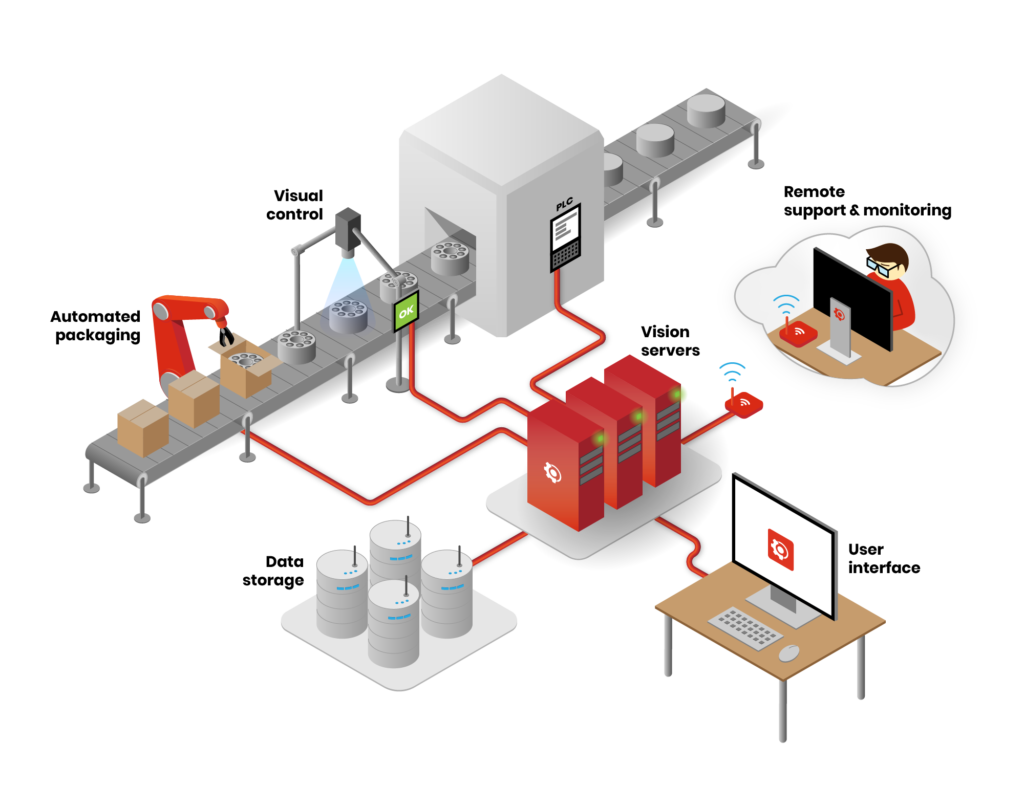

How does it work?

industrial.VISION is foremost intelligent universal software that connects individual parts of the production system. The heart of Vision software is based on distributed architecture to guarantee unmatched stability.

All processes and calculations run on independent servers that process all data from production systems and images from cameras. The system also monitors automated sections of the production line. All data is stored in the database and accessible through the user interface. Developers maintain the system remotely without ever interrupting the production process.

Visual control

industrial.VISION uses machine vision for visual control. This is based on recognition of different pixels and their patterns. Using neural networks and artificial intelligence, we can teach the system to recognize and then check, in real time, object colours and the presence of objects, measure distances, scan multiple code types and much more. The detection algorithms are continuously enhanced by machine learning.

Automation

We not only automate quality control but also different workstation types. The industrial.VISION system also controls and monitors robots. Robot movements are controlled by the ROS (Robot Operating System), which lets us dynamically respond to production needs.

User interface

industrial.VISION is designed with the user in mind to be as simple as possible to use for both the quality manager recording and analysing production and the production line operator monitoring activity along the line.